THE FINAL PART TO SETTING UP YOUR HOME GARAGE:

|

| “so listen up, punks!” |

Compressors don’t only run spray guns. Yes, as I mentioned in Post 4, we can get air drills, air sanders, air grinders, air chisels, and more to run with compressors. Most air tools don’t need anything like the amount of air that a spray gun requires, and good professional spray guns use in the region of 11 to 14 Cubic Feet per Minute (CFM). I’ll save you all the mathematical working out and tell you the answer. If you are going to spray properly, at a minimum, your compressor needs a 3HP motor.

The size of the tank isn’t that important, although the bigger it is, the less the compressor motor will run between feeding your tool with air. But, as with all things in engineering, there is a pay off. A bigger tank means a bigger piece of equipment which means more space taken up. I alluded to a separate and small lean-to type of building in Part 1 to house the compressor, family and neighbors permitting. If you get a compressor, I would really recommend this course of action and run the air line in through the wall. Coincidentally, a 3HP compressor at the moment is the largest we can get that runs on single phase electricity (AKA 120-volt AC service), which is convenient. If you don’t intend to paint with it then you could go for a smaller 2HP unit and save a few bucks, but you won’t save a massive amount, and you’ll kick yourself later if you change your mind about doing any painting.

My recommendation is to put compressed air in your shop. I don’t do this often, I prefer to lay out the facts and let people choose, but I can’t emphasize how useful compressed air is. From blowing the kid’s – and your own – tires (Yes, I worded that to get a giggle out of ya!), to blowing out carb jets, to painting stuff, it’s one of the most useful tools you can own. Not to mention that once you have one you have access to all the less expensive and more reliable air tools that you’ll be able to use.

Now on to welders. Good grief! This is really a subject that I could do a whole article about. I’m going to be quite brief because if you can weld already, you don’t need me to confuse things for you and if you can’t, you won’t learn how to from an article on the internet. You’ll have to take a course or at the very least team up with a buddy who has all the gear and get him/her to teach you.

There are four major welding disciplines in use today, two minor ones, and a couple of high-tech laser based systems in use by NASA, the aviation industry and I believe the Volkswagen Group (Volkswagen, Audi, Bentley, Bugatti, Lamborghini, SEAT, Skoda, and Scania).

We are really only interested in the major four. We’ll leave the high tech stuff to the aliens and their Luftewaffe buddies in the USA.

It would be downright criminal of me if I didn’t warn you that if you can’t weld, don’t attempt it without some instruction. I have literally seen bike frames come apart at the seams and the consequences of that happening are never very pleasant. Please DO NOT take chances, YOU MIGHT DIE!

Now let us briefly look at the disciplines anyway. This way if you know what they are, it should help you decide whether or not you want to learn them.

|

| tig welding for dummies! |

1. Oxy-Acetylene (OA) welding (commonly called gas welding). I’m sure you’ve all seen examples of this done. There are two large gas bottles; one is black (oxygen) and one is red (acetylene). These two gasses get mixed at the nozzle of the welding torch and are lit to produce a very hot and small blue flame that will melt steel very quickly. The idea is to melt the two pieces of steel together in a small continuous pool and fill in between with a filler rod made of steel. It’s a very skillful process and hard to do without a lot of practice and instruction. OA used to be the way almost everything automotive was welded. It’s very effective because the welder has to pay attention to every inch of weld he’s welding, therefore a bad weld is actually quite difficult to achieve. It’s drawback on sheet metal is that it’s a long process relative to the other disciplines and that can cause distortion on flat panels. That’s not a lot of use to us in bike building.

2. Arc Welding. This is the old type of industrial process used on everything from pipelines running through Alaska to truck chassis. It’s fast and cheap and it’s relatively easy to learn. The operator has an electrode (AKA the welding rod) attached to an insulated grip, and the piece to be welded is attached to an earth lead between it and the welding machine. To weld, the operative touches or “arcs” the electrode to the workpiece and the subsequent short circuit melts the metal. The happy worker bee fills in between the metal pieces with his electrode filler rod. As I say, the plus to arc welding is that it’s cheap, quick and easy to learn. It’s downside is that because of the amperages involved, arc welding thin gauge metal can be next to impossible without the absolute state of the art welding machine and a very good welder, which means it’s only really useful for heavy stuff. Again, not a great deal of use for bike building.

3. Metal Inert Gas (MIG) Welding. This is a welding process that was originally developed back in the 1940’s for welding aluminum and other non-ferrous metals. MIG welding is a semi-automatic process in which a wire connected to a source of direct current acts as an electrode (much like the Arc Welding process) and joins two pieces of metal as it is continuously passed through a welding gun. A flow of an inert gas (usually Argon) is also passed through the welding gun at the same time as the wire electrode. This inert gas acts as a shield, keeping airborne contaminants away from the weld zone. In it’s favour MIG has a lot going for it; it’s quite easy for the beginner to learn, it’s a fast procedure which makes it suitable for sheet metal, and it’s in common usage and therefore relatively cheap. Both the cost of the welding machines themselves and the consumables are what I consider affordable to the garage builder. The drawback is that it is very easy for the beginner to think that he/she has a good weld but in actual fact the weld doesn’t have enough penetration. It’s very easy to do “pretty” welds with a MIG, but pretty welds are not necessarily good welds. I would advise getting some instruction!

4. Tungsten Inert Gas (TIG) Welding. TIG welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by a shielding gas, usually an inert gas such as Argon, and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant-current welding power supply produces energy which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma. This is the popular process used in bike building today. See photo on the left of the sort of weld it is possible to achieve using TIG. The process is actually a cross between gas welding and MIG, in so much as the welder needs the skills of the gas welder in technique which is very similar, but the welding process is pretty close to what happens in MIG welding, where the electrode is manually introduced instead of fed automatically from a spool in the machine. Nearly all the bike builders and factories today TIG weld their frames. The plus side of TIG is that the welds are nearly always very good to perfect, dependent on the skill of the operator, for the same reasons as gas welding. The downside is the equipment is expensive, it is also arguably the most difficult welding technique to master and therefore, GET SOME INSTRUCTION!

The next two items we are going to look at putting in our workshop are a tube bender and a frame jig. If you want to build your own frames, or even change up any original donor frame, these two really are a must. So don’t be a dumbass and start cutting up the frame of your bike to put in a fancy single down tube without a frame jig. Don’t even hardtail your original frame without one. Seriously. You’ll just build some unrideable piece of ****.

We’ll start with the bender.

|

| jd squared – model 3 | tube bender |

1. Tube bender. To bend structural tube, which is what bike frames are made of, we need a decent bender. There are a few on the market. One is a ratchet bender called the JD Squared, Model 3. This is a very good bender for the small operative or the home builder. I have owned and used one in the past and it works very well. I believe it to be reasonably priced ($295), and if your budget would allow it then I would definitely recommend one of these as an option. They are robust and relatively straightforward to operate, but when bending something like 1.25″ CFS 3 (DOM seamless) for example, it is necessary to use a long handle and a second pair of eyes to watch the degree wheel and make sure you don’t bend too many degrees! You can keep pulling and checking and pulling and checking but besides being time consuming, the one thing that benders will not do if you go to far is bend it back! It should be noted that a hydraulic adapter be fitted to the Model 3, which negates the long handle and turns it back into a one man operation but, as with all things, this accessory has a price ($95).

Another bender is the Pro 3 from Pro Tools. This type of bender in my humble opinion is far easier to use, and we are less likely to go past our desired bend point because we are looking directly at the gauge. Although it has to be said that it costs 40% more and I like the JD Squared Model 3. These two are good examples of what’s out there on the market today.

One thing to bare in mind if you’re thinking about buying a bender is to determine if the machine itself is merely a paperweight without die sets. You can see in the video above that dies are needed and there are costs involved in buying them. If you’re thinking of doing different types of frames, instead of repeating the same one over and over, or simply building one, then you will need at least 7/8″, 1″ and 1.25″ die sets and more from 150 to 300 bucks a pop. You can see how it can turn into a big investment. Know what tubing you’re using, build with that, and go from there. Let a new client’s deposit for some other diameter pay for your new die set.

|

| home made bender 1 |

|

| home made bender 2 |

Look at these “Bite My Shiny Metal ***” pics above. You’ll see that in principle it is pretty much the same as the Pro 3 setup, but more compact, even as the idea is the same. See, an hydraulic ram pushes the die set around and bends the tube to the required degree. I mention the “Bite My Shiny Metal ***” bender above because we are on a budget, and this is a home-made option. You can Google “home made benders” and maybe you’ll find something cool and affordable.

The cost in total when I built this bender was under 50 bucks plus the die set. In fact I saved at least the cost of one die set if not two by building my own bender. If there is enough interest I will make the drawings available through bikerMetric at a future date and write an how to article on how to build one. It really isn’t difficult, with the tooling we have talked about having in our shop above in place I would label the task as an “easy to medium” level in difficulty.

You will see from looking at the two popular options above that bending tube is a serious and not a very cheap business. Although having said that, you will find that once you have a bender in your shop you will develop a whole new network of ‘friends’ who want this or that bending, in short it’s not beyond the realms of possibility that it could pay for itself before long.

2. Frame jig. This is a controversial subject. Everyone has an opinion on what is required of a frame jig. Let’s start by getting things in perspective. There are two types frame jigs and both of them have only one purpose; to hold pieces of tubing firmly relative to each other that enable us to weld them together precisely. The first type of frame jig, which every motorcycle builder must have, is very basic and has no adjustability in it since it is designed to hold a certain dimension of “part” (say a 1979 Yamaha XS650) and is only used time after time for builds of one model/size frame only (like building multiple 1979 Yamaha XS650s). These are known as “production jigs” and are used in factories which turn out multiple frames that are exactly as the one preceding the other day after day.

Excuse me. I had to yawn.

For a “production jig,” all one has to do is clamp and reclamp…[EDITOR’S NOTE: Dammit, Matt, you said “bender.” Clamps has nothing to do with our agreement!]… the precut/bent pieces of tube in and weld them together. These jigs are a fast and efficient way of holding pieces of tube relative to each other to build a frame.

The second type of frame jig i call an “adjustment jig,” because it has adjustment abilities dialed in to it at every level; including rake, wheelbase, ground clearance and more. They are used by factories for research and development and prototyping. Chances are the first frame on any production model out there was pulled off one of these jigs, with measurements duly taken on the fitments and clamps from production jigs then made up to match it’s configuration to go into production. The re-configured jig is then set, possibly for the next concept based off it’s original design.

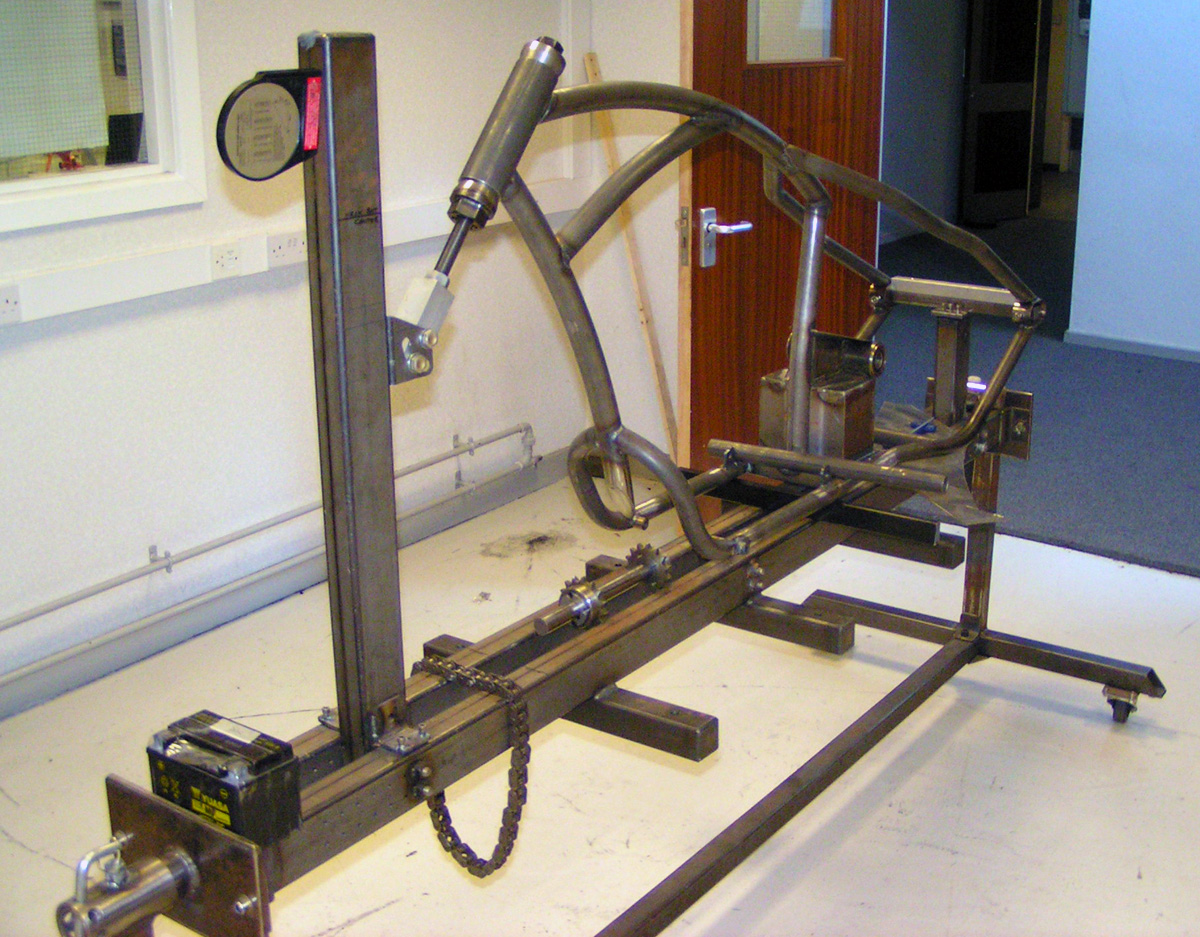

The reality is we need an “adjustment jig.” It’s very unlikely that the first frame idea we come up with, however killer it’s design, is going to satisfy us forever. When we want to build another one, we are either delving back into our pockets to build another jig or to fund modifying the one we have, which isn’t what we want any more because we might want different frame parameters. If you want to go to the lengths of building your own frame, it just doesn’t make sense financially or other wise to build a production jig. Take a look at the frame jig photo below:

|

| adjustment jig – front |

The jig above is on a bench where a guy or gal is able to get all around it to weld and curse that the sandwich hasn’t arrived and there is no beer. It’s a pretty common set up made basically of a thick steel bed with the jig fixtures either welded to it or bolted down through pre-drilled and possibly tapped holes. The neck is adjustable for both rake and height. It’s a neat and tidy set up and should work well for all garage builders. Considering that for us, space is at a premium, we would need this to be easily wheeled or moved out of the way when it’s not is use.

|

| adjustment jig – side |

The photo above, taken in a naughty gynecologist’s office, you see a jig that is movable, fully adjustable for all aspects of the frame, and can be rotated to facilitate welding the lower rails and underneath without having to take the frame out of the jig very often. In fact, with this jig we can weld almost completely around every frame tube and when we do take it out, it’s only to finish welding the last hard-to-get-to areas. The only reason to put the frame back in the jig after that is to check and see that no misalignment has occurred in the final stages.

That is a frame jig’s most important aspect; to keep frames straight. Without one, you’re a pretender and again, building a bike that will be unsafe and unrideable. You’ll kill yourself or somebody else that way.

As you can see a frame jig is not a half-assed affair and needs to be sturdy and able to hold various fitments and clamp the frame tubes in place whist they are welded together.

The jig in these pics are known as “Mr. Stiffy” (a very naughty gynecologist) and like the bender, if there is enough interest shown I will make the drawings to build this jig available through bikerMetric at some time in the future and do an article on how to build one.

The last item to mention in this two thousand and twelve-piece article is an adjustable bike stand or lift. On my planet there are only two types:

|

| rich people slumming on bikerMetric… |

|

| you. |

See the pics above for what they look like. Keeping in mind our constant need to be wary of space (or the lack of it) and money. I’d suggest the first example might be too large for us. Yeah, it could work in the space we have available but it takes up too much room in my opinion the cost could be better spent elsewhere, such as beer and BJs, or an air compressor and proper saws. Then there is what to do with it when not in use. It’s a big item even when static.

So what to do? We really do need something to allow our pride and joys to progress and develop. It’s great to have the bike up off the floor at a level where we are not constantly on our knees or bending over and putting strain on our backs, knees and elbows. Yes, we could build it up on a bench or table placed in the center, and that would certainly get rid of the bending and knee problems, but what do we do when it’s finished? The bike is not so easy to get down when complete as it is easy to get up there in pieces. Have a look the last photo above. These things really are a godsend. Get one. End of discussion.

The last piece of equipment I will mention is a fridge! Yep, a fridge.

Remember, your brew kit for tea/coffee/cocoa whatever, and kettle will all be neatly occupying a small corner of a bench somewhere ready for use periodically. You need somewhere to put your milk. I don’t care if you take yours black, I don’t, and if I decide to pay you a visit one day you’ll be very embarrassed to not be able to offer me my coffee how I like it after I’ve gone to all this trouble to tell you all these things and more. A fridge is also a jolly good place to store your beer for other peoples visits, like Trent’s, and a bottle of wine for visits from Frank and hot babes you want to impress.

If you want an engineering reason for a little refrigerator, store your Loctites, graphite greases and CopperLube in there as well. Oh, and Super Glue. Refrigeration makes it harder to get out that way but it lasts longer without solidifying.

I’m finishing the tools saga here and now. It’s time to move on and actually put this fantastically well equipped super space to use and build a bike.

If there is anything you guys think I’ve missed or haven’t covered in enough depth, feel free to f**k off contact me through bikerMetric and ask away. Please remember that the only “stupid question” is the one that you were either too afraid or too embarrassed to ask! Nobody knows everything, and even seemingly simple questions make us think.

Next time we will look at frames:

Do we buy one or do we make one? That’s the dilemma we’ll be discussing. There are pros and cons to both routes as we will see.

Stay tuned and watch this space. Oh, and two sugars in my coffee.

And to complete our legal agreement, I must end this segment with “matt groening.”

Get the best of bikerMetric directly in your inbox, once a week, every week.

[wysija_form id="1"]

bikerMetric custom metric bobbers, choppers, and cafe racers by honda, yamaha, kawaski, and suzuki

bikerMetric custom metric bobbers, choppers, and cafe racers by honda, yamaha, kawaski, and suzuki

Informatively awesome as usual. I just bought a cheap MIG welder and have always thought the same thing; there is no way I’m using it on the frame until I learn more, buy a better welder, and have my will drawn up.

thanks! really helpful always dreamin to open a new shop for custom bikes!

you are doing great at what you do already, man! when i am king of the world, you will be the minister of motorcycles in manila.